What is a Damper Actuator and How Does it Work?

In the world of HVAC systems, a Damper Actuator plays a crucial role. According to John Anderson, an expert in building automation, "A Damper Actuator is essential for efficient airflow control." This device regulates the flow of air, maintaining comfort and energy efficiency.

Damper Actuators are often overlooked, yet they influence indoor climates significantly. They open and close dampers in response to signals from the system. This action ensures that air distribution is optimal, affecting heating and cooling efficiency. However, the technology behind them can be complex and sometimes prone to failure.

The effectiveness of a Damper Actuator hinges on precise calibration and maintenance. Neglecting these details can lead to improper airflow and wasted energy. Users must recognize the importance of ongoing assessments. Engaging with experts can help address potential issues early. Thus, understanding the function of a Damper Actuator is essential for anyone involved in HVAC management.

What is a Damper Actuator?

A damper actuator is a crucial component used in heating, ventilation, and air conditioning (HVAC) systems. It is designed to control the airflow in ducts by adjusting the position of dampers. This adjustment affects the distribution of air, ensuring optimal temperature and air quality in indoor environments. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), properly functioning damper actuators can increase system efficiency by up to 30%.

These actuators come in various forms, including electric, pneumatic, and hydraulic models. Each type has specific use cases and benefits. Electric actuators are commonly used due to their precise control and easy integration with modern building management systems. Pneumatic actuators are reliable but may lack the precision required in some applications. Some installations still use hydraulic actuators, but they can be complex and costly to maintain.

Despite their importance, not all damper actuators perform equally. Factors such as installation errors or improper calibration can lead to inefficiencies. A study conducted by the U.S. Department of Energy found that nearly 20% of HVAC issues stem from malfunctioning actuators. Ensuring proper maintenance and timely replacement is essential. Ignoring these factors can result in increased energy costs and reduced comfort for building occupants.

Types of Damper Actuators and Their Applications

Damper actuators play a critical role in HVAC systems. They control the flow of air by adjusting dampers in response to system requirements. There are different types of damper actuators, including electric, pneumatic, and hydraulic models. Each type has unique applications suited to specific environments.

Electric damper actuators are widely used in commercial buildings. According to a 2022 industry report, electric models account for over 60% of the market. They provide precise control, ideal for optimizing energy efficiency. Pneumatic actuators, while less common, are applied in places where air pressure can be used effectively. Their simplicity makes them reliable in certain conditions.

Hydraulic actuators, often found in industrial settings, offer significant power. These actuators can handle larger dampers, but their complexity sometimes leads to challenges. Proper maintenance is vital, as neglect can result in performance issues. Selecting the right actuator type depends on the specific requirements of the system and environment. While many options are available, the choice isn’t always straightforward.

How Damper Actuators Function Mechanically

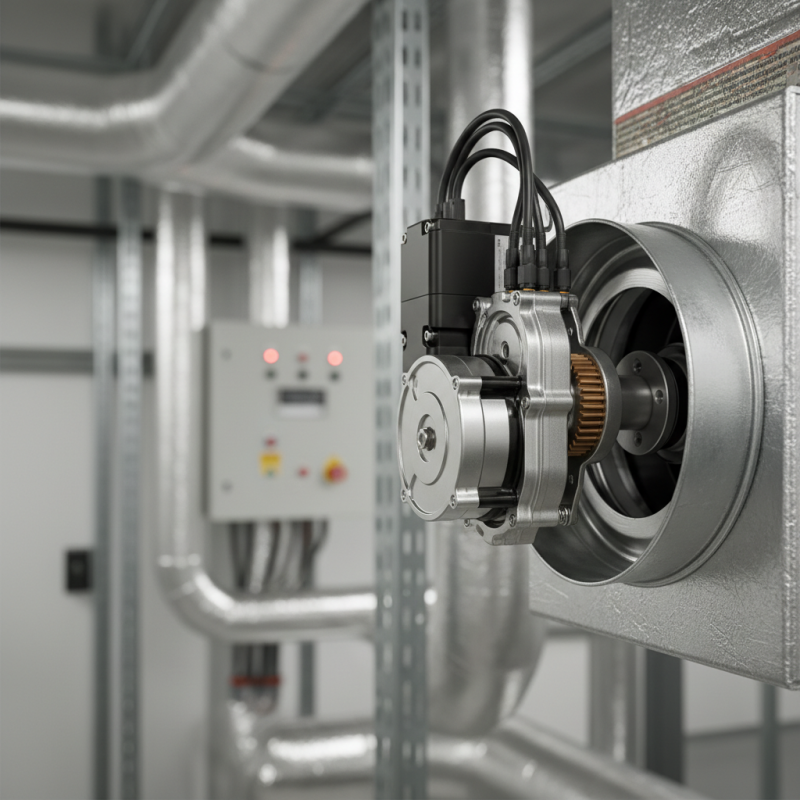

Damper actuators play a crucial role in controlling airflow within heating, ventilation, and air conditioning systems. These devices adjust the position of dampers, which are plates that regulate air flow in ducts. When the actuator receives a signal, it moves the damper accordingly. This process ensures the optimal distribution of air throughout a building.

Mechanically, damper actuators typically consist of a motor and gears. The motor receives electrical signals to determine the needed adjustments. Gears translate this motion into the movement of the damper. However, there can be issues. Sometimes, gears might wear down, causing delays or incorrect positioning. Regular inspections can help address these faults before they become larger problems.

In addition to mechanical failures, the responsiveness of damper actuators can be influenced by external factors. Temperature fluctuations can affect the actuator's efficiency. It's important to consider these environmental aspects. Understanding the mechanical function of damper actuators can help in their maintenance. Proper care can extend the life of these vital components.

Installation and Maintenance of Damper Actuators

When considering the installation and maintenance of damper actuators, attention to detail is crucial. Proper setup can influence system efficiency. An estimated 20% of HVAC failures can be traced back to poor actuator installation. It's essential to ensure that actuators are aligned correctly to optimize airflow. Misalignment may lead to premature wear of components and increased energy costs.

Regular maintenance practices are vital for long-term functionality. Industry studies suggest that routine inspections every six months can prevent major breakdowns. Look for signs of wear or damage in both the actuator and damper. Cleanliness is also important; dust and debris can interfere with operation. In fact, 15% of airflow issues originate from dirty components.

However, it’s easy to overlook these details. Many systems operate without regular checks, leading to inefficiency. Without proactive maintenance, small issues can escalate into costly repairs. Investing time into these practices enhances both performance and lifespan. Consider developing a maintenance schedule to ensure your damper actuators function optimally.

Common Issues and Troubleshooting Tips for Damper Actuators

Damper actuators play a crucial role in HVAC systems. They control airflow in ducts, enabling efficient temperature management. However, these devices can encounter problems that affect their performance. Understanding common issues is essential for effective troubleshooting.

One frequent issue is the actuator not responding to signals. This can stem from electrical faults or wiring problems. Often, users overlook simple checks like ensuring power supply or inspecting connections. Another problem is the actuator sticking due to debris or lack of lubrication. Regular maintenance can prevent this. Cleaning the actuator and ensuring smooth movement can help resolve this.

Calibration issues can also arise. An improperly calibrated actuator may not open or close fully. This can result in uneven airflow. Users should engage in routine checks to ensure the unit functions correctly. Adjusting the actuator settings might require some technical skill. Nonetheless, a little patience can lead to significant improvements in operation.