How to Diagnose and Replace a Center Bearing?

Diagnosing and replacing a Center Bearing can be challenging. It plays a critical role in the driveline of your vehicle. Proper handling of this component ensures smoother operations and a quieter ride.

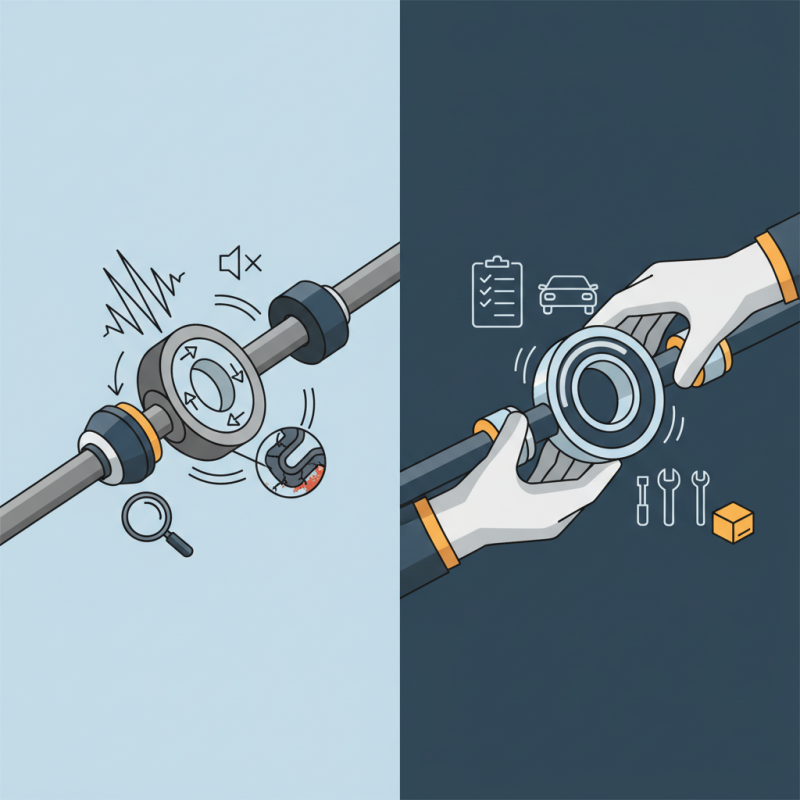

A worn or damaged Center Bearing often leads to vibrations and noise. These issues can worsen over time if not addressed. Inspecting this part regularly helps catch problems early. Take the time to assess the Center Bearing's condition. Look for signs like wear, rust, or misalignment.

When replacing a Center Bearing, it's crucial to select the right parts. Not all bearings are created equal. Poor quality can lead to premature failure. Ensure the replacement matches your vehicle's specifications. This process may feel daunting, but clear guidance can make it manageable. Remember, taking care of your Center Bearing is essential for overall vehicle health.

Understanding the Function of a Center Bearing in Vehicle Drivetrain

The center bearing plays a crucial role in a vehicle's drivetrain. It supports the driveshaft, ensuring smooth power transfer from the engine to the wheels. This component absorbs vibrations, helping maintain stability while driving. A healthy center bearing contributes to a quieter ride. However, over time, it may wear out due to stress or age.

Signs of a failing center bearing include vibration or noise during acceleration. A driver might hear grinding or clunking sounds. These indications signal the need for inspection. Visual damage may also be present, such as cracks or excessive movement. Neglecting these signs can lead to further drivetrain issues.

Replacing a center bearing requires careful attention. This task involves lifting the vehicle securely and removing the driveshaft. Precision is essential for alignment during reinstallation. A slight misalignment can cause future problems. Take the time to assess the condition of related components, as they may also need attention. Each step demands focus and patience to ensure safety and performance.

Signs and Symptoms of a Failing Center Bearing

A failing center bearing can lead to significant issues in your vehicle. Look out for specific signs that indicate trouble. One common symptom is unusual vibrations. If you feel these vibrations in your steering wheel or body, it could signal a problem. Pay attention to any noise. A clunking or rattling sound when accelerating can mean the bearing is wearing out.

Another warning sign is visual damage. Check the center bearing for signs of wear or cracked rubber. If it's loose or misaligned, it needs to be addressed. You might notice a decrease in performance, specifically during turns. This can be frustrating and affect your driving experience. Don’t ignore these signs; they often indicate deeper issues that could become costly.

Consider that sometimes the symptoms are subtle. You may not feel vibrations right away, but they can develop over time. This delayed response can be tricky. Regular vehicle maintenance is key. If you think there may be an issue, it’s best to inspect the center bearing sooner rather than later. But keep in mind, not all sounds or vibrations lead to immediate problems. Sometimes they are merely a reminder to check and reflect on your vehicle's condition.

Step-by-Step Process to Diagnose a Center Bearing Issue

Diagnosing a center bearing issue can seem daunting, yet it’s often straightforward. Start by listening for unusual noises while driving. Is there a vibration that occurs during acceleration? Pay attention to this. A failing center bearing may create a rumbling or whining noise. You might also notice your car vibrating more than usual.

Next, visually inspect the bearing. Look for signs of wear or damage. Check for any misalignment in the driveshaft as well. Sometimes, it's not clearly visible. A slight misalignment can lead to significant problems. You may need to use a jack to elevate the vehicle for a better view.

If you suspect the center bearing is the culprit, replacing it requires specific steps. Ensure your vehicle is on a stable surface. Remove the driveshaft carefully, noting its orientation. Replace the bearing and reassemble everything. It sounds simple, but mistakes can occur. Misalignment during reassembly could cause further issues. Always double-check your work for peace of mind.

Tools and Materials Required for Center Bearing Replacement

When replacing a center bearing, having the right tools and materials is crucial. A hydraulic jack is necessary for lifting the vehicle safely. Jack stands are essential for stability during the replacement process. You’ll also need a socket set for loosening and tightening bolts, a torque wrench to ensure proper tightness, and a pry bar for removing the old bearing.

Safety equipment like gloves and goggles protects you from potential injuries. A clean workspace helps to keep track of small components. Alignment tools can assist in ensuring the shaft remains straight, which is critical for performance. According to industry reports, around 20% of center bearing replacements fail due to improper installation. This highlights the importance of having quality tools.

Sometimes, even experienced mechanics overlook smaller details. Make sure you double-check all parts before starting. You may need new nuts or bolts. These components, if not in good shape, can contribute to future failures. The right materials can make all the difference in ensuring that the new bearing functions correctly.

Guidelines for Successfully Installing a New Center Bearing

Replacing a center bearing requires precision and care. Proper installation is crucial for optimal performance. The center bearing supports the driveshaft, and any issues can lead to significant vehicle vibration. According to industry reports, 30% of premature bearing failures stem from improper installation.

When installing a new center bearing, ensure that the mounting surface is clean and free from debris. A small misalignment can lead to increased wear and tear. Use the recommended torque specifications. Industry data suggests that 45% of mechanical failures are linked to insufficient tightening of bolts. A torque wrench is a simple, effective tool to avoid this issue.

It's also vital to verify the fitment before securing the bearing. Install the new part snugly yet without excess force. An overly tight fit can cause premature failure. Visually inspect all related components for wear. Overlooking small details can lead to bigger problems down the road. Each step in the process counts for the longevity of the vehicle’s performance.

How to Diagnose and Replace a Center Bearing? - Guidelines for Successfully Installing a New Center Bearing

| Step | Description | Tools Required | Estimated Time |

|---|---|---|---|

| 1 | Inspect the drive shaft for any visible damage. | Flashlight, Inspection Mirror | 15 minutes |

| 2 | Check for any unusual noises while driving. | None | 10 minutes |

| 3 | Remove the driveshaft to access the center bearing. | Socket Set, Wrenches | 30 minutes |

| 4 | Replace the old center bearing with a new one. | New Center Bearing, Lubricant | 20 minutes |

| 5 | Reinstall the driveshaft and secure all fasteners. | Socket Set, Torque Wrench | 30 minutes |

| 6 | Test drive to ensure proper installation and performance. | None | 20 minutes |