What is a Lamination Machine and How Does It Work?

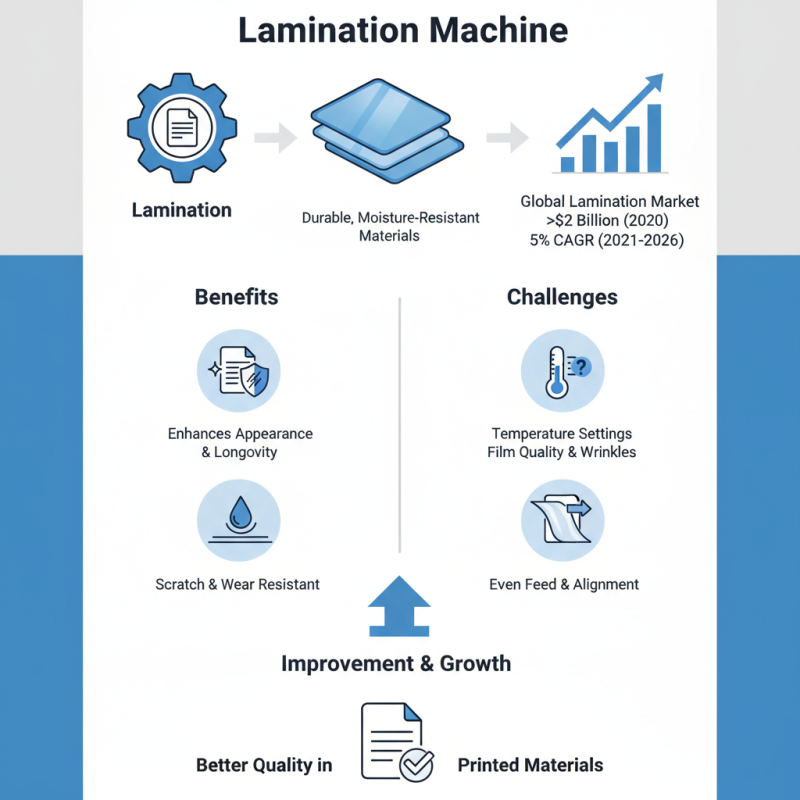

In the realm of printing and packaging, the Lamination Machine plays a crucial role. This equipment is essential for creating durable, moisture-resistant materials. According to industry reports, the global lamination market was valued at over $2 billion in 2020. It is projected to grow at a CAGR of 5% from 2021 to 2026. Such growth highlights the importance of this technology.

A Lamination Machine processes documents, photos, and cards by enclosing them in a protective layer. This process enhances both appearance and longevity. For instance, laminated surfaces are resistant to scratches and wear, increasing their usability. However, not all laminating methods yield optimal results. Often, users struggle with temperature settings or film quality, affecting the final product.

Though the benefits are significant, achieving perfect lamination can be challenging. Operators must ensure even feed rates and proper alignment to avoid wrinkles or bubbles. Awareness of these obstacles is essential for improvement and growth in the industry. The Lamination Machine remains a vital asset, contributing to better quality in printed materials.

Definition and Purpose of a Lamination Machine

A lamination machine is a device used to cover and protect documents. It applies a plastic layer to materials like paper. This process enhances durability and gives a polished look. Many people use these machines in offices and schools for valuable documents.

The purpose of a lamination machine is to preserve important papers. It shields them from damage, moisture, and tearing. Laminated papers are often easier to clean. However, not everyone uses lamination wisely. Some may laminate items that shouldn't be altered. It's important to reflect on what should be preserved.

Using a lamination machine can be straightforward. You place the document inside a plastic pouch and feed it through the machine. The heated rollers bond the plastic to the paper. Yet, sometimes, people face issues like bubbles or uneven lamination. Achieving perfection requires practice and patience. It's essential to consider whether lamination is truly necessary before proceeding.

Lamination Machine Usage Statistics

Types of Lamination Machines Available in the Market

Lamination machines come in various types, each serving different needs. The most common types are cold laminating machines and hot laminating machines. Cold laminators use adhesive sheets to seal documents. They require no heat, making them user-friendly and safe for delicate materials. Hot laminators, on the other hand, use heat to seal and protect documents. They offer a stronger bond, ideal for items subject to wear and tear.

Another type is the roll laminator. These machines are great for businesses that need to laminate large quantities. They can handle wide documents, making them efficient for banners and posters. Additionally, pouch laminators are compact and work well for smaller projects. They are often used in offices and schools.

Tips: Always read the manufacturer’s guidelines before use. This ensures optimal results and prolongs the machine’s life. If you laminate often, consider the size and weight of the machine. Bulky machines may require dedicated space.

Remember that not all materials are suitable for lamination. Some may warp or bubble, especially under heat. Test a corner of the item first to avoid potential damage. Additionally, keep the machine clean to prevent residue buildup, which can affect performance.

The Lamination Process: Step-by-Step Guide

The lamination process is vital for preserving important documents. It involves several key steps. First, the material to be laminated is cleaned and prepared. This is crucial. Dust and fingerprints can ruin the finish. According to industry reports, a clean surface enhances adhesion by up to 50%.

Next, the lamination machine applies heat and pressure. The laminating film is fed through rollers. These rollers melt the adhesive on the film, creating a bond. An average laminating cycle takes about 10 to 15 minutes, depending on the thickness of the material. This is where errors can occur. If the temperature is too high, bubbling may happen. If not enough, delamination can occur.

Finally, the laminated product is trimmed and cooled. This step is often rushed, leading to uneven edges. A study indicated that about 20% of laminated pieces show signs of post-lamination tears or wrinkles. Care must be taken to avoid these issues. Attention to detail is essential to achieve a professional finish.

Common Applications of Lamination Machines

Lamination machines are essential tools in many industries. They protect documents, enhance durability, and provide a polished look. Various applications exist for these machines, each serving unique purposes.

In offices, lamination machines are frequently used. Employees often laminate important reports or presentations. This process helps prevent damage from spills and tears. In educational settings, teachers laminate flashcards and posters. These materials last longer and withstand daily use. Laminated items look professional and are visually appealing.

Retail and marketing also benefit from lamination. Businesses laminate promotional materials like brochures and signs. Bright colors and glossy finishes catch the eye of potential customers. However, overusing lamination can create waste. It’s crucial to weigh costs and benefits for sustainability. Choosing what to laminate is essential for resource management.

Maintenance and Care for Lamination Machines

Lamination machines are essential for preserving documents and enhancing their longevity. To ensure they function effectively, regular maintenance is crucial. Dust and adhesive residue can build up over time, affecting performance. It's advisable to clean the machine's rollers and surfaces frequently. A soft cloth can remove debris without causing scratches.

Checking the temperature settings is vital as well. Overheating can damage materials, while low temperatures might not seal properly. Sometimes, using test materials can help find the right balance. Pay attention to the input and output areas; jams happen easily. If a jam occurs, investigate the cause before resuming work.

Sometimes, users forget to check for frayed wires or loose connections. These issues may lead to significant malfunctions. Regular inspections can catch potential problems early. Remember, a well-cared-for lamination machine can save time and improve output quality. So, take the time to reflect on your maintenance routine.