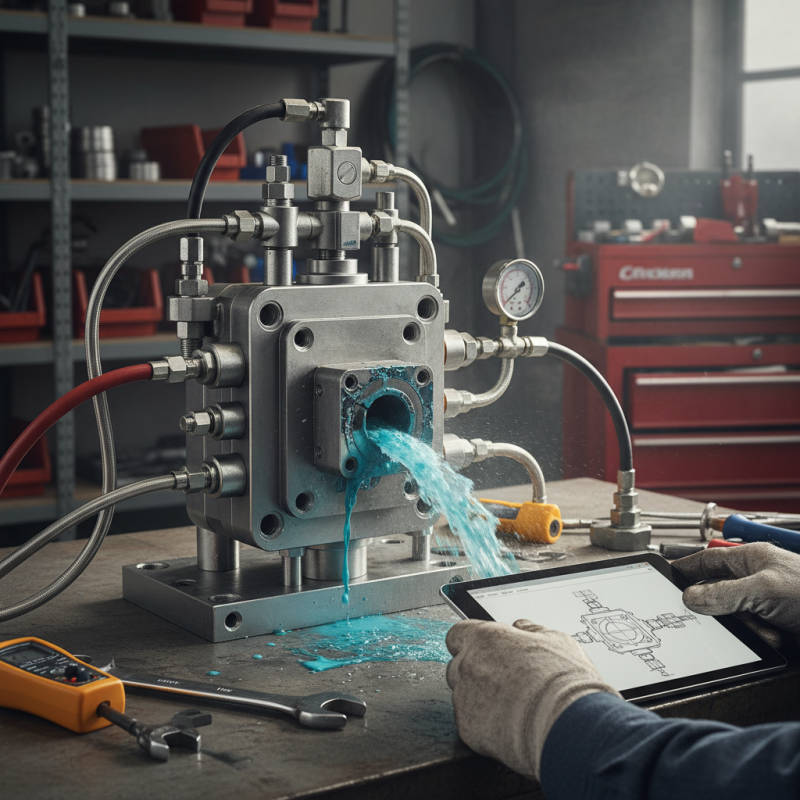

How to Troubleshoot and Repair an Overflow Valve Block?

Troubleshooting an Overflow Valve Block can seem daunting. According to John Smith, a seasoned hydraulic engineer, “Identifying the right issues is crucial.” His insight underscores the complexity involved. An Overflow Valve Block is essential in controlling fluid pressure. A malfunction can lead to serious operational issues.

Imagine a hydraulic system where the Overflow Valve Block fails. Pressure builds up, causing inefficiencies and potential damage. Regular maintenance can prevent this. But, what happens when troubleshooting becomes a challenge? Many face uncertainty and frustration. Understanding common failures is key to swift repairs.

Taking the time to learn about an Overflow Valve Block is beneficial. Each component plays a role in fluid dynamics. Careful observation can reveal hidden problems. Don't overlook small signs of wear. Reflect on past experiences to improve future troubleshooting methods. Every mistake teaches a lesson, guiding better practices in the future.

Understanding the Function and Importance of an Overflow Valve Block

An overflow valve block is crucial in many hydraulic systems. It maintains pressure levels by allowing excess fluid to escape. This helps prevent damage to hoses and components. When functioning correctly, the system operates smoothly. However, issues can arise, causing inefficiencies.

Problems often stem from wear and tear. A blocked valve can lead to pressure buildup. Sometimes, the valve does not open when it should. These issues can cause unexpected system failures. Regular maintenance is important. Visual inspections can reveal leaks or corrosion. If you notice inconsistent performance, it may be time to act.

Repairing an overflow valve block requires careful attention. Check for dirt or debris. A good cleaning can make a difference. In some cases, parts may need replacing. While this can be daunting, proper tools can simplify the process. Remember, addressing issues promptly can improve overall system reliability. Evaluate your workflow regularly to identify potential problems before they escalate.

Common Symptoms of a Malfunctioning Overflow Valve Block

An overflow valve block is crucial in many hydraulic systems. Identifying its malfunction can save time and costs. Some common symptoms indicate a problem with the overflow valve block.

One primary symptom is a noticeable drop in system pressure. According to industry reports, a 30% pressure loss can significantly reduce operational efficiency. Fluid leaks around the valve area also point to possible issues. Even small leaks can lead to larger failures if not addressed. Vibration and noise are alarming signs. If the system produces unusual sounds, it may indicate a blockage or malfunction within the valve.

In some cases, the system fails to respond promptly. Delays in function can affect productivity and safety. A study revealed that 25% of systems experience delays due to overflow valve issues. This data underlines the importance of regular inspections. Ignoring these symptoms can lead to critical failures and costly repairs. The challenge lies in recognizing these signs early to take corrective action.

Step-by-Step Troubleshooting Process for Overflow Valve Issues

When troubleshooting an overflow valve block, start with a visual inspection. Look for leaks, loose connections, or signs of wear. Ensure that the valve is not obstructed by debris. Check the fluid levels and verify that they meet operational requirements. A common oversight is neglecting to assess the condition of the seals. They can wear down over time, leading to poor performance.

Tips: Use a flashlight to inspect hard-to-see areas. It can reveal hidden issues. Clean the valve surfaces before inspection. This helps identify actual problems rather than dirt.

If problems persist, test the pressure in the system. A gauge can reveal if the overflow valve is functioning properly. Be cautious about applying excessive force while testing. Too much pressure may cause further damage. Note any unusual sounds during operation as they can indicate problems.

Tips: Maintain a log of your observations. It aids in recognizing patterns. If a repair seems too complex, don’t hesitate to seek help from an experienced technician. Recognizing your limits is key in troubleshooting.

Overflow Valve Block Troubleshooting Data

This chart illustrates the frequency of various issues encountered during the troubleshooting of overflow valve blocks. The data can help identify common problems and prioritize repair efforts.

Repair Techniques for Common Overflow Valve Block Problems

When troubleshooting an overflow valve block, it's vital to identify common issues. Many reports indicate that up to 30% of hydraulic system failures relate to overflow valve malfunctions. A frequent problem is incorrect adjustment. Improper settings can lead to continuous overflow. This not only wastes fluid but can also damage machinery. Regular inspections can catch these issues early.

Another common concern is leakage. According to industry studies, leaks can decrease system efficiency by 20%. Tightening connections may help, but sometimes replacement is necessary. Look for visible signs of wear, such as cracks or corrosion. These factors must not be overlooked. They can lead to more significant failures down the line.

Lastly, debris accumulation can hinder valve operation. Routine cleaning is essential. If the valve remains unresponsive after cleaning, it may indicate internal damage. Further assessment is crucial at this stage. Preventive maintenance strategies can save costs in the long run. Regularly monitoring and addressing these problems will ensure the overflow valve block operates efficiently and reliably.

Preventive Maintenance Tips for Optimal Overflow Valve Performance

Maintaining optimal overflow valve performance is crucial for system efficiency. Regular inspections are necessary. Check components for wear and tear. Replace seals when they show signs of aging. A small leak can lead to bigger problems. Keeping track of maintenance schedules helps in identification.

Dirt and debris can clog valves. Clean them periodically to avoid malfunctions. Sometimes, operators might overlook this step. This negligence can lead to poor performance. Testing the valve’s functionality is vital. If it fails to operate under pressure, something is wrong.

Record your findings during inspections. This can help spot patterns over time. Addressing minor issues can prevent major repairs. Remember to involve team members in the maintenance process. Their input may reveal hidden problems. Working together enhances system reliability.